Our history

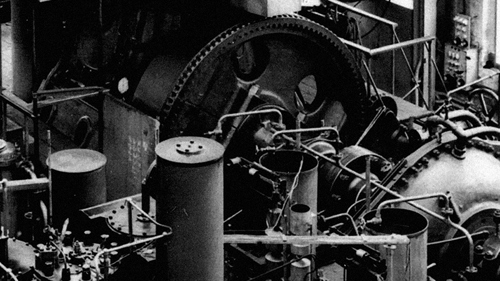

WinGD originated from the diesel engine business of Sulzer Corporation in Winterthur, established in 1893 when the Sulzer Brothers signed an agreement with Rudolf Diesel for his new engine technology.

Sulzer started diesel engine manufacturing in 1903 in Winterthur.

In 1986 the last diesel engine left the Winterthur facility. Going forward to November 1990, Sulzer established its Diesel Engine & Diesel Power Plant Division as a separate company, New Sulzer Diesel Ltd.

In April 1997, New Sulzer Diesel Ltd. merged with Wärtsilä Diesel Oy to create Wärtsilä NSD Corporation which later became Wärtsilä Corporation. The Swiss company, Wärtsilä Switzerland Ltd., responsible for low-speed, two-stroke engine within Wärtsilä, was merged with China State Shipbuilding Corporation (CSSC) in early 2015 and renamed Winterthur Gas & Diesel Ltd. (WinGD). In 2016, Wärtsilä Corporation transferred its remaining shares of WinGD to CSSC making WinGD 100% owned by CSSC.

The engine brand was changed from 'Wärtsilä' to ‘WinGD’. Today WinGD supports its engines with state-of the-art digital technologies, training and warranty services.

WinGD continues the long tradition of the Sulzer Diesel Engine business founded in 1893.

1900's

In 1905 the first reversing two-stroke marine engine was developed by Sulzer. It led the way to the first valve-less two-stroke engines at sea, two 559 kW Sulzer 4SNo.6a engines in the Italian cargo ship ‘Romagna’ in 1910.

In 1912 the first ocean-going ship with valve-less crosshead type two-stroke engines was the German cargo ship ‘Monte Penedo’, which was equipped with two Sulzer 4SNo.9a engines with a total of 1250 kW. Developments rapidly followed thereafter with engines for rail traction, submarines, a 1000 mm-bore research engine, a broader range of engine types and sizes for ship propulsion, marine auxiliary duties and land-based power plants, increased power outputs, lowered fuel consumption, and improved reliability.

1920's

Sulzer was a famous name for Diesel engines in ships, power plants, and railways around the world.

1930's

Airless fuel injection became standard from 1930 in all engine types, greatly improving their efficiency and reducing their maintenance requirements. The next step was the development of turbocharging, greatly improving the power concentration of the engines with less weight and less space requirements.

1940's

The first turbocharged two-stroke diesel engine in normal operation was a Sulzer 6TAD48 engine in 1946 in the power house of the Winterthur facility.

1950's

Turbocharging became standard in marine low-speed engines for ship propulsion, which opened the chapter of the long series of Sulzer R-type low -speed engines – the RSAD, RD, RND, RND-M and RL types.

1970's

The first low-speed marine engine in the world running on gas entered service in 1972. The Sulzer 7RNMD90 engine was running on natural gas in the Norwegian 29,000m3 LNG carrier Venator.

1980's

A radical change in scavenging from loop to uniflow was made in 1983 with the introduction of the RTA low-speed engines of 380 to 840 mm cylinder bore, increasing to 960 mm in 1994. In 1981 tests with electronically-controlled fuel injection began on a four-cylinder research engine.

1990's

In 1998 the world’s first large, electronically-controlled low-speed engine with common-rail injection was introduced and running in the Diesel Technology Centre in Oberwinterthur, Switzerland leading to the launch of the RT-flex commonrail system.

2000's

The first RT-flex engine entered service in September 2001. The world’s largest Diesel engines are now the 14-cylinder RT-flex96C engines of 80,080 kW (108,920 bhp) of which the first entered service in September 2006.

2010's

In February 2011 a project began to develop dual-fuel gas engine technology for low-speed engines as a solution for complying with the upcoming IMO Tier III NOX emission limits without additional exhaust after-treatment. Only seven months later, on the 19th of September, the new technology was successfully demonstrated on a full-scale research engine at the Wärtsilä factory in Trieste, Italy.

Later in 2011 Generation X-Engines were introduced to the market, offering greater efficiency in terms of fuel consumption and emissions. In 2012 the large bore X92 engine was added to the Generation-X engine portfolio. This engine type serves the market for large and ultra-large container vessels.

Aside from the significant fuel cost savings, the X92 engine directly reduces the emission levels of carbon dioxide, making it easier for the shipyard to achieve a better Energy Efficiency Design Index (EEDI).

In 2013, WinGD introduced the X-DF engine series. Dual-fuel engines , using gas admitted at low pressure and ignited by a low volume of liquid pilot fuel was a breakthrough in the marine industry. The X-DF engines offer new marine standards with low-pressure gas technology.

2020's

In 2020, the first vessels powered by WinGD's 12X92DF, the GUINNESS WORLD RECORDSTM most powerful Otto-cycle engine came into operation.Through the extensive operational experience of the X-DF fleet, WinGD was able to identify further optimisation potential and launched X-DF2.0, reducing methane slip by up to 50% and improving energy efficiency.

WinGD

Our people

Our people are at the heart of our engines. Their passion for innovation and sustainability drives our success.

Over a century of experience

Our engine history

It all began with Rudolph Diesel and the Sulzer Brothers

12X92DF

Guinness World Record title

WinGD's 12X92DF most powerful dual-fuel engine.

Get in touch

Contact us

With offices around the globe we provide market specific solutions and services.