Our Portfolio

The WinGD X-DF genset portfolio for power generation includes both medium and large bore size engines with a power output ranging from 15MWe to more than 40MWe.

All engines are available in 7-cylinder up to 9-cylinder configuration. The WinGD X-DF low-pressure genset can either operate in natural gas or diesel mode. For power plants operating with natural gas, the WinGD X-DF low-pressure genset does not require the additional installation of a gas compressor station.

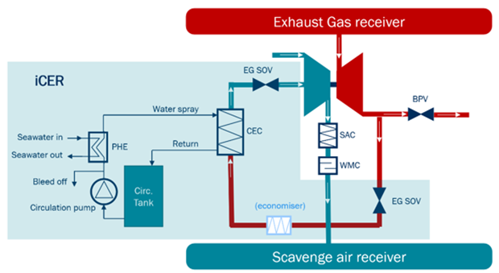

The WinGD X-DF genset is equipped with the Intelligent Control by Exhaust Recycling (iCER) system.

The iCER system delivers enhanced combustion control by recirculating part of the inert gas. The WinGD X-DF genset with the iCER system does not require the additional installation of an exhaust gas after treatment system to fulfil the European Emissions Regulations.* This advantage offers significant capital and operational cost savings which are normally associated with the Selective Catalytic Reaction (SCR) system.

Abbreviation:

| BVP | Back pressure Valve | CEC | Cascade Exhaust Cooler |

| SOV | Shut Off Valve EWG | EWG | EWG Exhaust Waste Gate |

| SAC | Scavenge Air Cooler | BTV | Blower Throttle Valve |

| WMC | Water Mist Catcher | PHE | Plate Heat Exchanger |

The iCER system is designed to recirculate up to 50 % of the exhaust gas back to the engine, replacing oxygen in the scavenge air inlet with CO2.

WinGD has developed a modular power plant solution to facilitate Engineering Procurement and Construction (EPC) projects. In close cooperation with leading EPC partners, a modular solution ensures low cost on initial investment as well as enhanced collaboration with local companies. WinGD is responsible to specify and deliver the X-DF genset together with all control panels and auxiliary systems. Also, WinGD can provide a long-term service agreement, including digital solutions for remote support and operations optimisation.

In close collaboration with Hudong-Zhonghua, the market leader in Liquefied Natural Gas (LNG) carrier construction, WinGD developed an Integrated Floating Storage Power Unit (iFSPU) solution. The iFSPU solution combines a high-efficiency power generation unit with the LNG storage and regasification equipment. This unique solution can meet the European Emissions Regulations without the additional installation of an exhaust gas after treatment system

The iFSPU solution serves the needs of both the onshore power generation unit and the local offshore gas distribution network. The iFSPU is powered by the WinGD X-DF genset to deliver high efficiency and reliability. The LNG storage capacity is modular in design and includes a capacity of up to 200,000 m3. Installation and testing of all components conveniently takes place directly at the shipyard. This approach enables the customer to benefit from a faster commissioning, while enabling them to take the delivery everywhere in the world. WinGD supports project specific assessments, enabling optimisation of the X-DF genset configuration and storage capacity. Furthermore, the iFSPU solution can also integrate a Battery Energy Storage Solution (BESS) to better support network systems with a higher share of renewable energy sources.

WinGD’s engineered components and services

- The WinGD X-DF Genset (Gas Engine & Generator)

- The Genset Auxiliary Rack (GAR) and base frames

- The iCER system for performance optimisation and emissions control

- The generator control panels

- The genset engineering and design integration with the modular power plant solution

- All required installation and testing

- All required logistics, including on-site supervision for reassembling activities

- Project management

- On-site commissioning

- Customer training

- A Long-Term Service Agreement (LTSA)

WinGD’s engineered components and services for the EPC partner

- On-site preparation and civil works

- The electrical balance of the plant

- The engine’s hall

- Fuel and lubricant storage

* For information only, project specific assessment is needed.

Contact information

E-mail: powerplant@wingd.com